- Inquiry

12 Ton Heavy Duty Welding Bottle jack

• Zinc plated long handle allows ease of pumping.

• Welded construction NO LEAK.

• Safety valve prevents the ram from being overextended and causing damage to the cylinder.

• Inner safety valve prevent the user to adjust the system.

• Arc surface bottom of the steel base to make the load in the center of the piston.

• Prevent rust with ENP (electroless nickel plating) ram piston, make it smooth, bright, and long life.

• Double seals in the pump to prevent the oil leak.

• Light weight forged base provides more steel only where strength is required.

• This design creates a better, stronger design with the tank welded directly to the forged base.

• Longer life than normal screw connection jack due to smooth bearing surfaces and close tolerances.

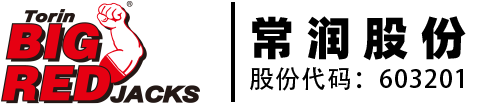

• Carrying handles on big capacity jack for easy transport.

产品参数

其他型号

关于产品

Product Information

Product Parameters

|

Model |

TH912001 |

Capacity |

12 Ton |

|

Min. Height |

236 mm |

Lifting Height |

160 mm |

|

Adjustable Height |

110 mm |

Max. Height |

506 mm |

|

N.W./G.W. |

8.52 / 8.77 kg |

Package Size |

755x185x270 mm |

|

QTY/CTN |

5 PCS |

QTY/20'CY |

1915 PCS |

Features

• Zinc plated long handle allows ease of pumping.

• Welded construction NO LEAK.

• Safety valve prevents the ram from being overextended and causing damage to the cylinder.

• Inner safety valve prevent the user to adjust the system.

• Arc surface bottom of the steel base to make the load in the center of the piston.

• Prevent rust with ENP (electroless nickel plating) ram piston, make it smooth, bright, and long life.

• Double seals in the pump to prevent the oil leak.

• Light weight forged base provides more steel only where strength is required.

• This design creates a better, stronger design with the tank welded directly to the forged base.

• Longer life than normal screw connection jack due to smooth bearing surfaces and close tolerances.

• Carrying handles on big capacity jack for easy transport.

Common Problems And Solutions

1. When lifting heavy weights, the mandril fails to rise to the maximum route. When the jack reaches a certain height, and the maximum route is not reached, the mandril cannot rise up any more, which indicates that there is a lack of working oil in the jack, and it should be replenished.

2. The mandril wobbles while rising. Generally the oil return valve is not closed tightly; we can tighten oil return valve needle in counterclockwise direction. If it is still unstable, check whether there is any oil leakage around the pressure rod; if the oil leaks, it indicates that the seal ring of the mandril is damaged, and it should be replaced. If there is no oil leakage, confirm again whether the oil return valve and the inlet valve is already locked, and also check sealing gasket conditions in the cylinder end joint of pressure rod; if all the above is normal, then it indicates that the seal ring is damaged, or the fixed screw is loosening, we should replace it or tighten the screw.

3. The mandril fails to rise while no-load. First check the oil amount of the jack, and we should add oil when insufficient. If jack is not short of oil, we can loosen the oil return valve needle of the jack, remove the oil plug of oil filling port, then trample on the jack base by our feet, repeatedly pull up the mandril and press down again by our hands for several times, in order to exhaust air; after the above actions are completed, tighten the oil plug of oil filling port and oil return valve tightly, and then try again the no-load mandril; if the mandril still cannot rise, lay jack flat, remove the oil return valve, check whether the valve and seat contact well; if there is dirt, it should be removed; if there is pit, slot and uneven, it should be replaced. Finally check whether the oil inlet valve is well sealed and the sealing ring of mandril is damaged or falls off. If any, replace it in time.

4. Oil leakage, can be seen by visual observation. The oil leakage area of the jack is usually in the base and the cylinder joint, around the mandril, in the lock thread of the oil return valve, in the fixed oil plug of the oil filling port, around pressure rod etc. The cause of oil leakage is usually the damage of sealing gasket, it must be replaced in time.

成分-

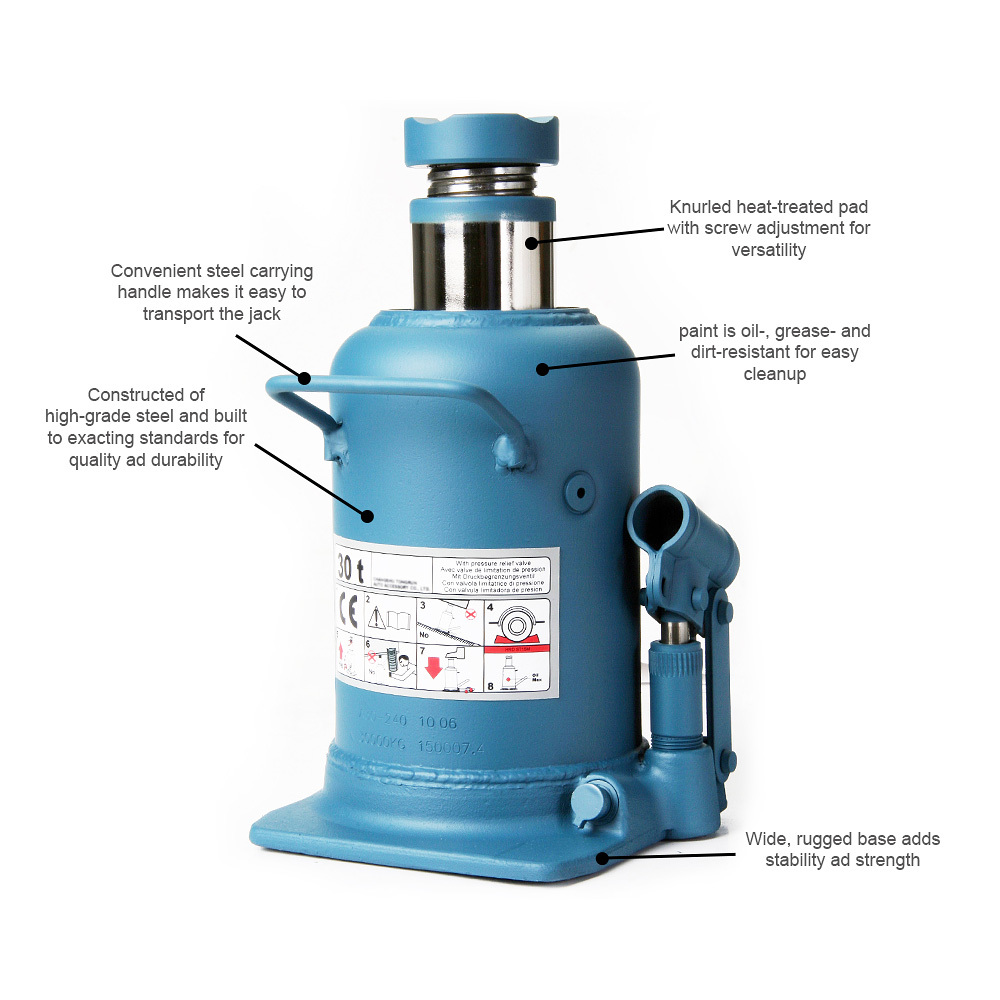

优质液压油,防止漏油

液压系统采用高质量的油,提供更好的耐腐蚀性和高/低温灵活性,允许单元在40华氏度和105华氏度之间的温度下运行。

自动焊接

该阀采用细钢焊接而成,操作方便,密封性好,性能可靠,具有自动锁气滴料功能。

高密度钢材

由高级钢材制成,并按照严格的质量和耐用性标准建造。

你可能也喜欢

型号

特点

• 安全阀

• 工业密封件

• 机器人焊接

• 激光切割框架

• 可拆卸零件托盘

• 双速泵

• 重型H型框架由高级钢制成,并按照严格的质量和耐用性标准建造

• 在彻底的化学清洗后应用无铅漆面,以确保持久的光洁度并帮助防止生锈

• 油漆是油,油脂和污垢,易于清理

• 高质量的大直径液压钢缸单元导致提高负载所需的较低油压,有助于减少磨损并延长使用寿命

• 活塞闸板经过处理和抛光,以防止打滑

• 活塞-ram采用带支撑环的y型聚氨酯密封圈,防止负载缓慢下降或绕过油漂移

• 液压系统采用高质量的油,提供更好的耐腐蚀性和高/低温灵活性,使设备能够在40华氏度和105华氏度之间的温度下运行

• 超长手柄包括容易抽吸力

• 专为大量商业用途而设计。

• 快速高效的空气泵减少提升时间。

• 硬化合金电镀ram最大的耐久性。

• 带集成过滤器的空气阀,密封液压单元。

• 重型空气马达提供最大功率。

• 防止污染。

• Designed for heavy commercial use.

• Fast efficient air pump reduces lifting time.

• Hardened alloy-plated ram for maximum durability.

• Air valve with integrated filter, seal hydraulic unit.

• Heavy-duty air motor provides maximum power.

• Prevents contamination.

• The hydraulic technology makes lifting simple while a wider frame and internal bypass valve ensure safety.

• Safety bypass system prevents over-loading and ensures safe operation.

• Steel casters for longevity.

• The hydraulic technology makes lifting simple while a wider frame and internal bypass valve ensure safety.

• Safety bypass system prevents over-loading and ensures safe operation.

• Steel casters for longevity.